The aerospace industry requires products that stability energy, pounds, and effectiveness under Excessive circumstances. Rifeng PMI Foam, crafted by among the list of primary PMI foam companies, offers a slicing-edge Answer tailored for these tough requirements. Its Fantastic Qualities allow it to be a crucial content in the development of plane, helicopters, and other Innovative aerospace factors. This blog explores the exceptional benefits of Rifeng PMI Foam and its apps in aerospace engineering.

Table of contents:

improving plane Structural Integrity with Rifeng PMI Foam

light-weight Solutions: cutting down fat without the need of Compromising power

Thermal balance of Rifeng PMI Foam in higher-Temperature Environments

scenario Studies: thriving Integration of Rifeng PMI Foam in Aerospace

improving plane Structural Integrity with Rifeng PMI Foam

Structural integrity is a cornerstone of aerospace layout, and Rifeng PMI Foam sets a fresh common During this crucial place. With its Excellent strength-to-weight ratio, it provides The best foundation for generating strong composite structures though retaining durability underneath substantial pressure and demanding situations. This Superior foam not simply boosts stiffness and influence resistance but additionally minimizes weight, which happens to be essential for accomplishing ideal effectiveness in aerospace applications. Its flexibility causes it to be a perfect choice for structural panels, plane radomes, along with other essential parts in which power and trustworthiness are non-negotiable. Engineers depend on its mechanical toughness to make certain security and performance, even in large-stakes, higher-efficiency environments for instance helicopter blades, unmanned aerial cars (UAVs), together with other slicing-edge aerospace technologies. Rifeng PMI Foam read more is often a trustworthy Alternative for pushing aviation and aerospace innovation to new heights.

Lightweight answers: decreasing body weight with out Compromising Strength

lowering excess weight is vital in aerospace to improve gasoline efficiency, General efficiency, and sustainability. Rifeng PMI Foam is particularly engineered by using a fine mobile construction that minimizes resin absorption for the duration of core shaping, causing considerably lighter closing elements. This advanced structure not merely lowers product bodyweight but additionally cuts down on resin usage, even further contributing towards the performance of output procedures. The distinctive features of this foam result in lower operational fees, diminished environmental effect, and improved energy efficiency, rendering it an excellent Alternative to the aerospace business. Despite its lightweight nature, Rifeng PMI Foam won't compromise about the mechanical properties of the material, guaranteeing sturdiness and dependability in demanding apps. By offering an ideal harmony of efficiency and negligible body weight, Rifeng PMI Foam happens to be a reliable choice for producers searching for revolutionary, Price tag-effective, and sustainable options for contemporary aerospace worries.

Thermal Stability of Rifeng PMI Foam in large-Temperature Environments

Aerospace parts are made to face up to Extraordinary environmental problems, which include powerful mechanical worry and significant temperatures. Rifeng PMI Foam stands out with its Remarkable thermal resistance, protecting security and reputable general performance regardless if exposed to curing temperatures of nearly one hundred eighty°C just after suitable cure. This Highly developed functionality guarantees its success in demanding production processes which include vacuum infusion (VARI) and resin transfer molding (RTM), the place thermal endurance is critical. Its remarkable thermal steadiness and longevity supply engineers with The boldness to use it in heat-critical and higher-functionality programs, like radome aircraft, aerospace interiors, and Highly developed structural composites. Rifeng PMI Foam not merely improves materials effectiveness but will also contributes to your longevity and security of aerospace components under hard disorders.

Case scientific tests: prosperous Integration of Rifeng PMI Foam in Aerospace

Rifeng PMI Foam’s impressive abilities are already properly applied in numerous aerospace assignments, showcasing its flexibility and benefit in higher-overall performance apps. For instance, its light-weight but sturdy Attributes have revolutionized helicopter blade production, substantially decreasing General rotor fat though boosting durability and operational effectiveness. This not just increases flight functionality but in addition can help lessen gasoline use and routine maintenance requires eventually. likewise, UAV (Unmanned Aerial auto) designers have greatly benefited from the foam’s lower resin absorption, which makes the production approach much more productive, and its impressive mechanical strength, which enhances flight performance and Total structural integrity, even beneath demanding circumstances. Moreover, the material has established indispensable inside the creation of radomes, where by its stiffness and Extraordinary bonding properties make certain reputable effectiveness, even in Severe environmental circumstances for instance high winds, temperature fluctuations, and dampness. These qualities make Rifeng PMI Foam an important component in advancing cutting-edge aerospace technological know-how.

In conclusion, the versatility and efficiency of the State-of-the-art foam material have created it an indispensable asset across various aerospace programs. Its one of a kind mixture of energy, light-weight style, and longevity proceeds to force the boundaries of innovation, enabling engineers to fulfill the demanding difficulties of recent aviation and past. With its demonstrated history, this materials is set to remain a critical element in future developments in the aerospace business.

Scott Baio Then & Now!

Scott Baio Then & Now! Amanda Bynes Then & Now!

Amanda Bynes Then & Now! Alexa Vega Then & Now!

Alexa Vega Then & Now! Charlie Korsmo Then & Now!

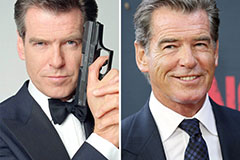

Charlie Korsmo Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!